Pro-Tect UV Systems feature durable, non-corrosive schedule 80 PVC reaction chambers. The schedule 80 PVC is more robust when compared to HDPE or polypropylene models and offers significant cost reduction when compared to 316 Stainless Steel. Pro-Tect UV systems are rated for operating pressures of up to 150 PSI*. The "L" shaped design used allows for proper hydraulic mixing inside the UV reaction chamber and optimizes the UV dose.

Pro-Tect UV systems utilize a single end lamp and quartz sleeve access that simplify maintenance and reduce over all cost associated with operating a UV system. Changing lamps and sleeves has never been easier. A quick "no tool needed" design allows for easy removal of lamp cables without the risk of twisting cables and causing damage. A special fitting allows the lamp cable to remain in place while the lamp nut is spun. A simple o-ring seal allows for easy changing of sleeves without the risk of breaking by removing thick walled rubber gaskets that tend to become brittle and stick to the sleeve. With Pro-Tect UV systems, you'll no longer need to worry about proper lamp placement. The distance from the cable crimp to the lamp connector are preset at the factory, allowing for proper placement of the lamp every time.

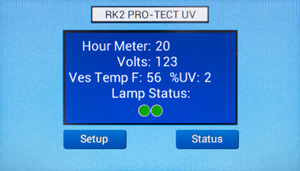

Complete Pro-Tect UV With Basic HMI Control Package

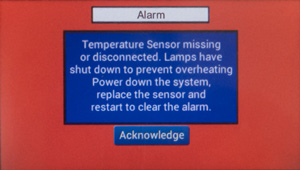

All Pro-Tect UV systems feature an over temperature safety cutoff. What makes Pro-Tects' temperature sensor different is that unlike other models with sensors in the main portion of the body or vessel, our sensor is located in the lamp bulkhead or end plate. Locating the sensor in the end plate protects critical sealing components from overheating and failing due to the close proximity of the lamp filament (hottest part of the system).

Pro-Tect UV HMI Controllers are manufactured using non-corrosive thermoplastic or fiberglass enclosures. Our HMI controllers have a NEMA Type 12 rating and are 508A UL listed. Pro-Tect's HMI control packages are user friendly and feature a color touch screen display showing basic operating status of the UV system and alerts users to any problems related to the UV system. Both the standard HMI and Pro Series packages include the over temperature safety cutoff as standard options. Upgrading to the optional HMI Pro series control package expands the capabilities of your Pro-Tect UV system. The HMI Pro series offers a larger color touch screen display and more advanced monitoring and control options.

Standard HMI Controller

Status Screen

Alarm Screen

Your application - Single pass, multi-pass (recirculation), etc.

Flow Rates - Normal, peak, do you have times with no flow? Do you ever flow water through the unit at higher than disinfection flow rates?

Target Organisms - Organisms of concern, UV-C delivered dose requirements.

Water Quality - UVT, turbidity.

Water temperature - Minimum and maximum required and present.

Installation Location - Indoors, outdoors, space availability for maintenance, i.e. lamp removal.

Lamp or System Orientation - Vertical or horizontal.

The above information is the basic information required in order to design a UV system for your application. You supplier will also have other questions they can assist you in answering and will also help you to understand the "why" behind your system design - as well as the "what".

For more information on UV and also Pathogens, visit our UV Information page

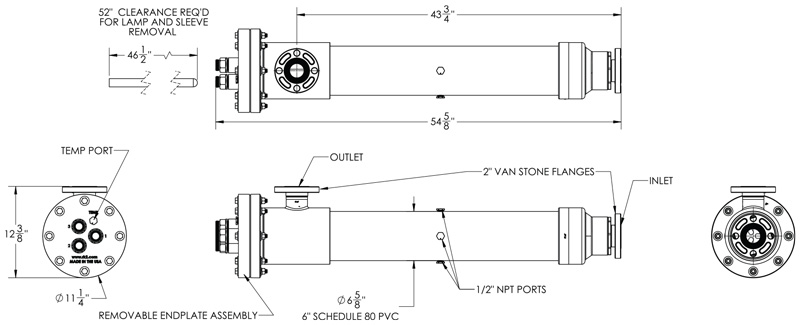

The ALH4 series is our "L" configuration using 130 watt amalgam lamps. They are designed for medium to moderate flow applications that may require a smaller footprint. These models use shorter 130 watt amalgam lamps. Amalgam lamps offer approximately twice the UV-C output compared to that of high output lamps used in our HLH series.

ALH4 Series Schematic

| Model | Lamps#/ Watts |

Input Watts | UVC Output | UV Vessel Dimensions AxBxC | Inlet/Outlet Sizes | Max PSI/BAR | 120-VAC Power Supply Dimensions HxWxD | 230-VAC Power Supply Dimensions HxWxD | Max Amps @ 120/230 VAC |

30 mJ/cm2 GPM/LPM |

180 mJcm2 GPM/LPM |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ALH41D6-XXX | 1/130 | 130 | 40 | 56" x 6" x 47" | 2", 3", 4", 6" | 150/10.3 | 16" x 14" x 8" | 24" x 20" x 10" | 2.1/1.0 | 66/255 | 11/42 |

| ALH42D6-XXX | 2/130 | 260 | 80 | 56" x 6" x 47" | 2", 3", 4", 6" | 150/10.3 | 16" x 14" x 8" | 24" x 20" x 10" | 3.9/2.0 | 112/434 | 18/72 |

| ALH43D6-XXX | 3/130 | 390 | 120 | 56" x 6" x 47" | 2", 3", 4", 6" | 150/10.3 | 18" x 16" x 10" | 24" x 20" x 10" | 5.8/2.9 | 161/624 | 27/104 |

| ALH43D8-XXX | 3/130 | 390 | 120 | 62" x 8" x 51" | 3", 4", 6", 8" | 130/8.9 | 18" x 16" x 10" | 24" x 20" x 10" | 5.8/2.9 | 228/883 | 38/147 |

| ALH44D8-XXX | 4/130 | 520 | 160 | 62" x 8" x 51" | 3", 4", 6", 8" | 130/8.9 | 18" x 16" x 10" | 24" x 20" x 10" | 7.5/3.7 | 296/1,147 | 49/191 |

| ALH45D8-XXX | 5/130 | 650 | 200 | 62" x 8" x 51" | 3", 4", 6", 8" | 130/8.9 | 24" x 24" x 10" | 24" x 24" x 10" | 9.4/4.7 | 346/1,341 | 58/223 |

| ALH46D10-XXX | 6/130 | 780 | 240 | 64" x 10" x 51" | 4", 6", 8", 10" | 110/7.5 | 24" x 24" x 10" | 30" x 24" x 12" | 11.2/5.6 | 480/1,860 | 80/310 |

| ALH47D10-XXX | 7/130 | 910 | 280 | 64" x 10" x 51" | 4", 6", 8", 10" | 110/7.5 | 24" x 24" x 10" | 30" x 24" x 12" | 13.3/6.5 | 564/2,185 | 94/364 |

| ALH47D12-XXX | 7/130 | 910 | 280 | 69" x 12" x 51" | 6", 8", 10", 12" | 90/6.2 | 24" x 24" x 10" | 30" x 24" x 12" | 13.3/6.6 | 648/2,511 | 108/418 |

| ALH48D12-XXX | 8/130 | 1,040 | 320 | 69" x 12" x 51" | 6", 8", 10", 12" | 90/6.2 | 24" x 24" x 10" | 30" x 24" x 12" | 15.0/7.5 | 763/2,956 | 127/493 |

| *Basic HMI And HMI Pro Series Control Options Available. | |||||||||||

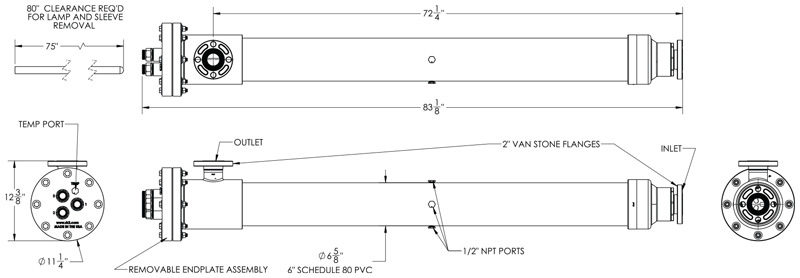

The ALH6 series is our "L" configuration using 320 watt amalgam lamps. These models are designed for moderate to high flow applications and for when space is not a concern. The amalgam lamps used offer approximately twice the UV-C output compared to that of high output lamps used in our HLH series. Generally speaking our ALH6 series will also require less lamps when compared to our ALH4 series models due to the larger 320 watt lamp used.

ALH6 Series Schematic

| Model | Lamps#/ Watts |

Input Watts | UVC Output | UV Vessel Dimensions AxBxC | Inlet/Outlet Sizes | Max PSI/BAR | 120-VAC Power Supply Dimensions HxWxD | 230-VAC Power Supply Dimensions HxWxD | Max Amps @ 120/230 VAC |

30 mJ/cm2 GPM/LPM |

180 mJcm2 GPM/LPM |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ALH61D6-XXX | 1/320 | 320 | 98 | 85" x 6" x 76" | 2", 3", 4", 6" | 150/10.3 | 24" x 20" x 10" | 24" x 20" x 10" | 3.2/1.6 | 165/639 | 27/106 |

| ALH62D6-XXX | 2/320 | 640 | 196 | 85" x 6" x 76" | 2", 3", 4", 6" | 150/10.3 | 24" x 20" x 10" | 24" x 20" x 10" | 6.0/3.0 | 276/1,070 | 46/178 |

| ALH63D6-XXX | 3/320 | 960 | 294 | 85" x 6" x 76" | 2", 3", 4", 6" | 150/10.3 | 24" x 20" x 10" | 24" x 20" x 10" | 9.0/4.5 | 392/1,519 | 65/253 |

| ALH63D8-XXX | 3/320 | 960 | 294 | 86" x 8" x 76" | 3", 4", 6", 8" | 130/8.9 | 24" x 20" x 10" | 24" x 20" x 10" | 9.0/4.6 | 587/2,275 | 98/379 |

| ALH64D8-XXX | 4/320 | 1,280 | 392 | 86" x 8" x 76" | 3", 4", 6", 8" | 130/8.9 | 24" x 20" x 10" | 24" x 20" x 10" | 12.0/6.1 | 744/2,883 | 124/480 |

| ALH65D8-XXX | 5/320 | 1,600 | 490 | 86" x 8" x 76" | 3", 4", 6" | 130/8.9 | 24" x 24" x 10" | 24" x 24" x 10" | 15.0/7.5 | 848/3,286 | 141/548 |

| ALH66D10-XXX | 6/320 | 1,920 | 588 | 88" x 10" x 76" | 4", 6", 8", 10" | 110/7.5 | 30" x 24" x 12" | 30" x 24" x 12" | 18.0/9.1 | 1,198/4,642 | 200/773 |

| ALH67D10-XXX | 7/320 | 2,240 | 686 | 88" x 10" x 76" | 4", 6", 8", 10" | 110/7.5 | 30" x 24" x 12" | 230 VAC 11.0 | 1,405/5,442 | 234/907 | |

| ALH67D12-XXX | 7/320 | 2,240 | 686 | 90" x 12" x 76" | 6", 8", 10", 12" | 90/6.2 | 30" x 24" x 12" | 230 VAC 11.0 | 1,611/6,243 | 268/1,040 | |

| ALH68D12-XXX | 8/320 | 2,560 | 784 | 90" x 12" x 76" | 6", 8", 10", 12" | 90/6.2 | 30" x 24" x 12" | 230 VAC 13.0 | 1,839/7,126 | 306/1,188 | |

| ALH613D12-XXX | 13/320 | 4,160 | 1,274 | 90" x 12" x 76" | 6", 8", 10", 12" | 90/6.2 | 40" x 32" x 12" | 230 VAC 21.0 | 2,000/7,571 Flow velocity limited | 405/1,533 | |

| *Basic HMI And HMI Pro Series Control Options Available. | |||||||||||

Our HLH series is offered in our HLH3 and our HLH5 series models. These units use 80 watt and 150 watt high output lamps respectively. These units should be used in applications the require low to moderate flow applications with low UV dose requirements.

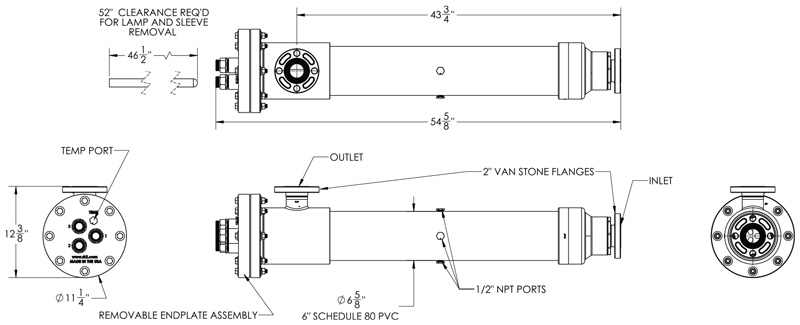

HLH3 Series Schematic

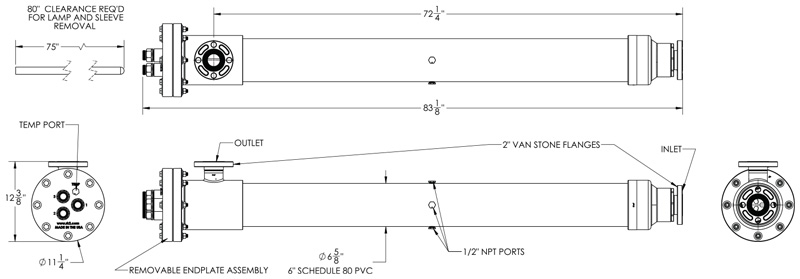

HLH5 Series Schematic

| Model | Lamps#/ Watts |

Input Watts | UVC Output | UV Vessel Dimensions AxBxC | Inlet/Outlet Sizes | Max PSI/BAR | Power Supply Dimensions HxWxD | Max Amps @ 120/230 VAC |

30 mJ/cm2 GPM/LPM |

180 mJcm2 GPM/LPM |

|---|---|---|---|---|---|---|---|---|---|---|

| HLH32D6-XXX | 2/80 | 160 | 40 | 56" x 6" x 47" | 2", 3", 4" | 150/10.3 | 14" x 12" x 8.4" | 3/1.5 | 81/314 | 13/52 |

| HLH33D6-XXX | 3/80 | 240 | 80 | 56" x 6" x 47" | 2", 3", 4" | 150/10.3 | 14" x 12" x 8.4" | 4.0/2.0 | 119/461 | 20/77 |

| HLH34D6-XXX | 4/80 | 320 | 120 | 56" x 6" x 47" | 2", 3", 4" | 150/10.3 | 16" x 14" x 8.4" | 5.0/2.5 | 155/600 | 26/100 |

| *Basic HMI And HMI Pro Series Control Options Available. | ||||||||||

| Model | Lamps#/ Watts |

Input Watts | UVC Output | UV Vessel Dimensions AxBxC | Inlet/Outlet Sizes | Max PSI/BAR | Power Supply Dimensions HxWxD | Max Amps @ 120/230 VAC |

30 mJ/cm2 GPM/LPM |

180 mJcm2 GPM/LPM |

|---|---|---|---|---|---|---|---|---|---|---|

| HLH52D6-XXX | 2/150 | 300 | 160 | 85" x 6" x 76" | 2", 3", 4" | 150/10.3 | 14" x 12" x 8.4" | 3.75/1.8 | 174/675 | 29/113 |

| HLH53D6-XXX | 3/150 | 450 | 200 | 85" x 6" x 76" | 2", 3", 4" | 150/10.3 | 14" x 12" x 8.4" | 5.5/2.7 | 250/969 | 41/162 |

| HLH54D6-XXX | 4/150 | 600 | 240 | 85" x 6" x 76" | 2", 3", 4" | 150/10.3 | 16" x 14" x 8.4" | 7.5/3.7 | 331/1283 | 55/214 |

| *Basic HMI And HMI Pro Series Control Options Available. | ||||||||||

Previously, we have discussed how to properly size and design a UV treatment system. RK2 can also help you determine, clarify and solidify the factors that will drive the system design. Did you know that many of these factors can change throughout the year? Care is taken to ensure that you, the customer, will have a UV system that protects your investment.

But what about service and support? One of the keys to a satisfied customer market is the support after the sale. Be it maintenance support, parts or just advice about the use and care of your UV system, a good supplier will always be there in a timely way to help you.